High Resolution Images and Illustrations

Licence to use Photo Library: You may download the pictures from the Photo Library section for editorial purposes only for use in any format so long as it is not detrimental to The Dryerbox brand, reputation or goodwill. You agree that you shall not alter, modify or deface these pictures in any way whatsoever. The copyright in all The Dryerbox Photo Library are and shall remain the property of InOvate Technologies, Inc. or its licensors. Any and all The Dryerbox Photo Library used for any purpose, including but not limited to editorial purposes shall bear the words "The Dryerbox".

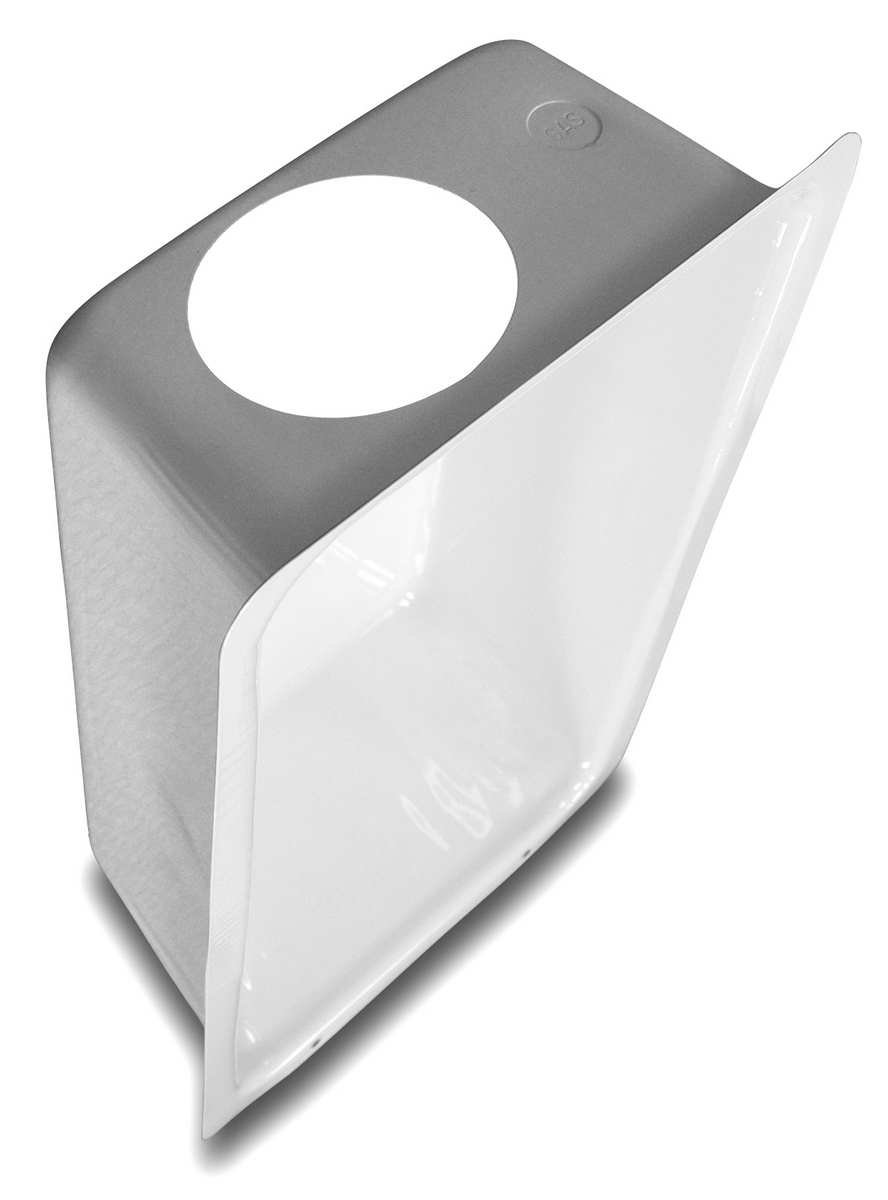

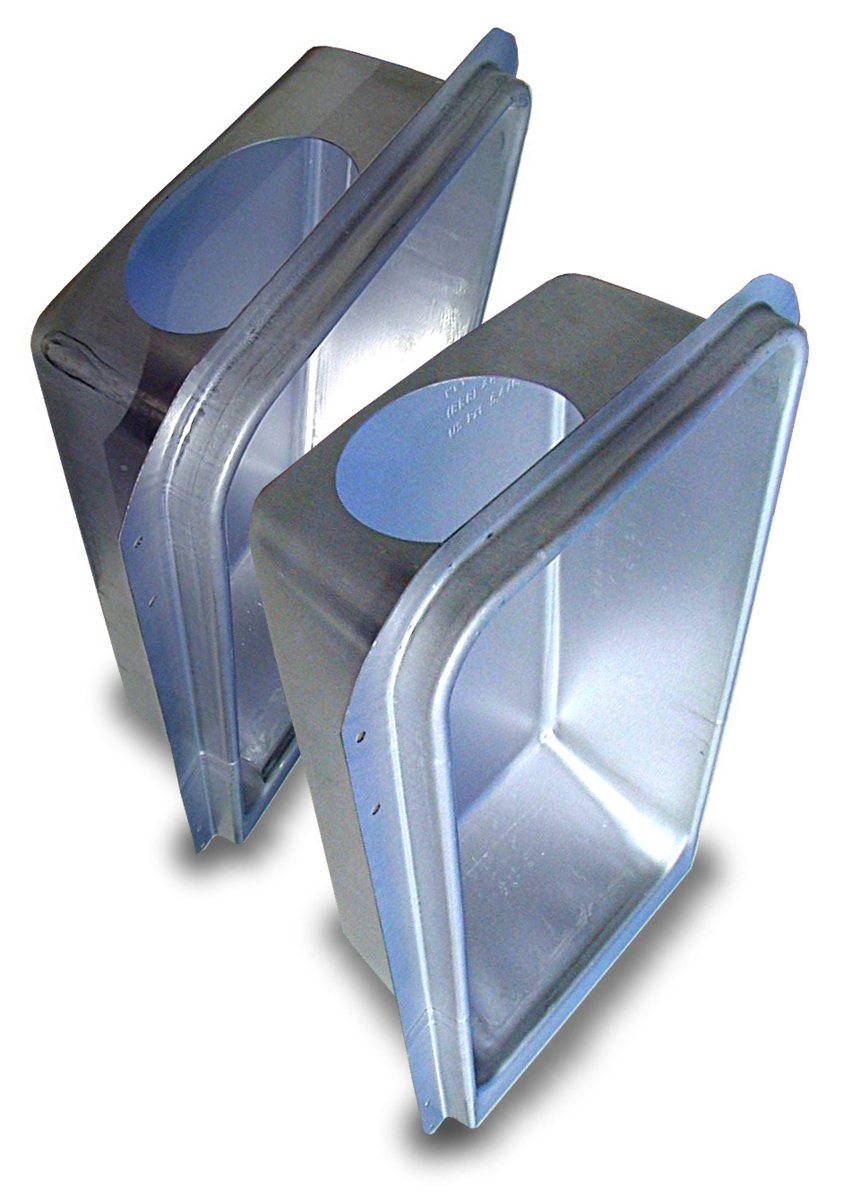

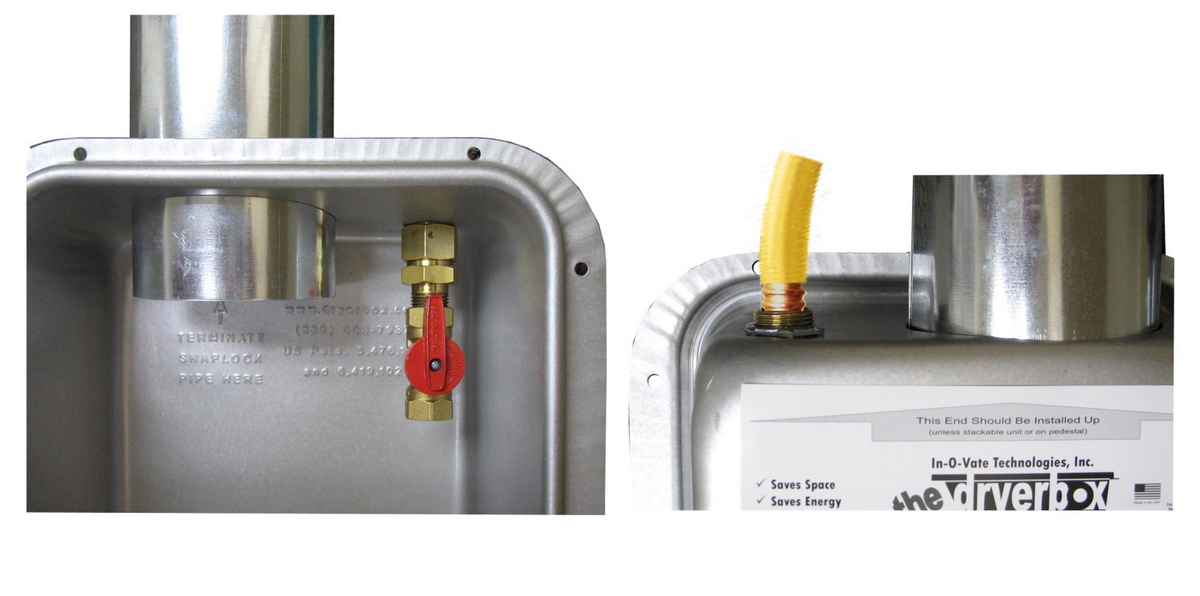

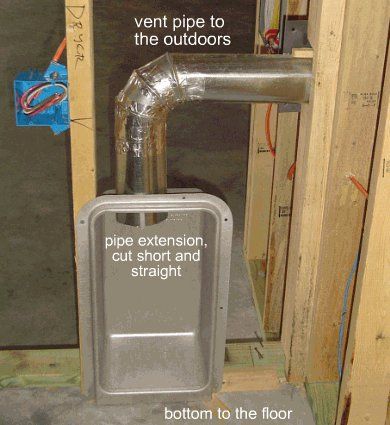

~-480dryerbox.jpg)

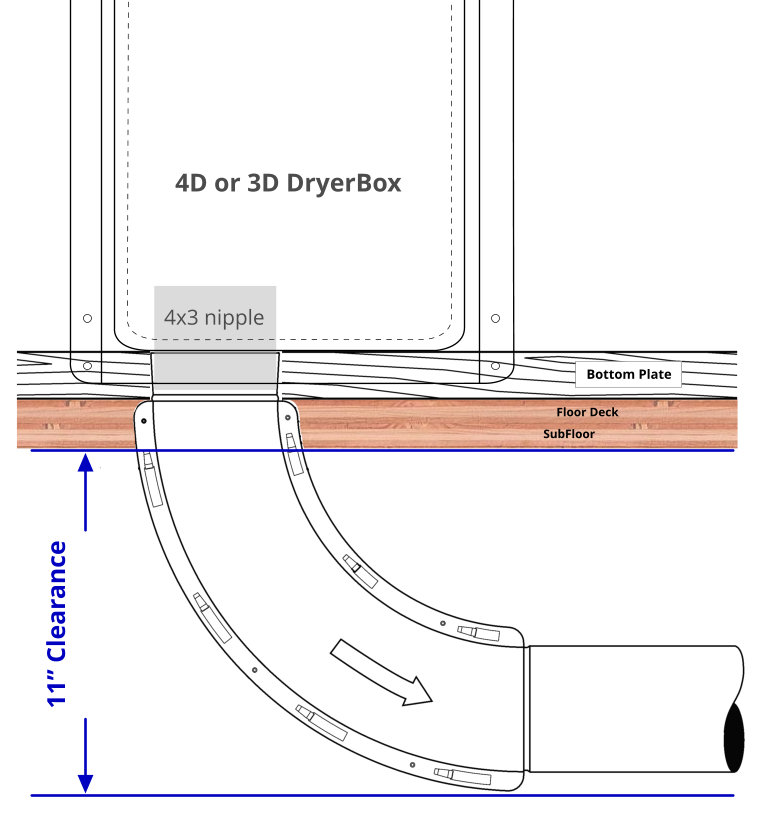

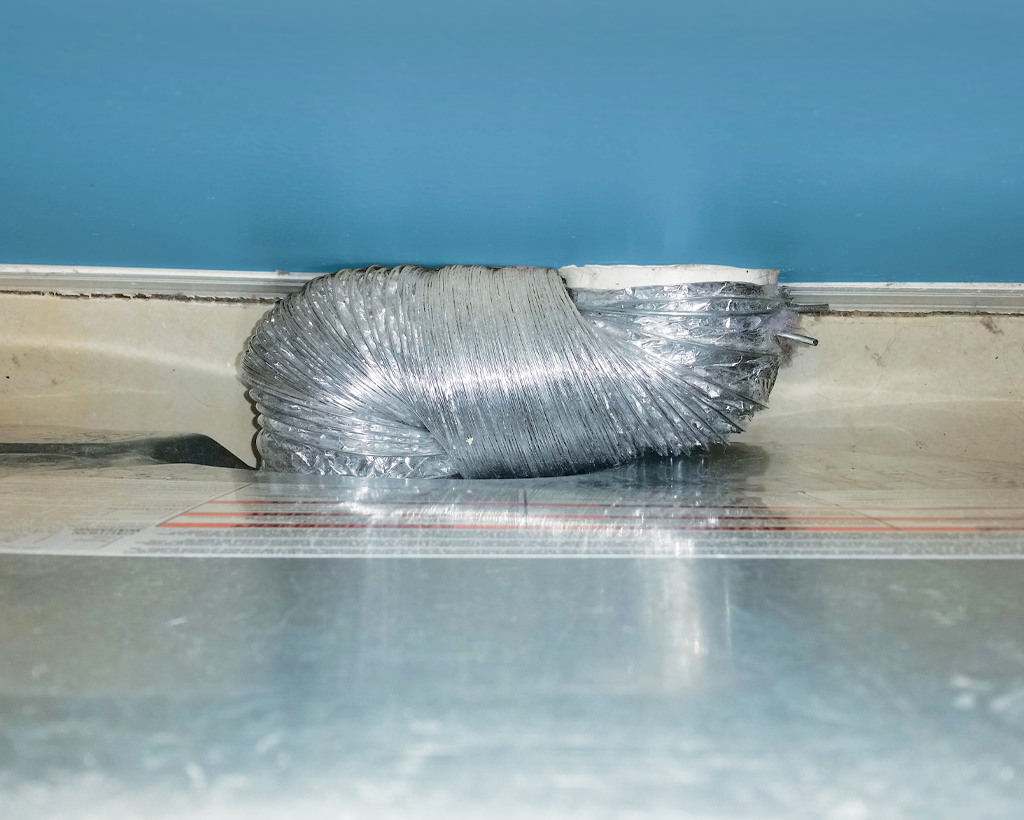

~-2 Pics Flex.jpg)